Quality management

CONTINUOUS IMPROVEMENT

The ISO-9001 standard requires a continuous improvement process.

Certified quality management is one thing and the will to actually implement an attitude of rigorous quality awareness is another: day by day, batch by batch, workpiece by workpiece. The LITEC Feintechnik team lives by this. We achieve the best possible quality thanks to perfect interplay between man and machine.

Flexibility

Flexibility throughout the company ensures that delivery dates are kept and on-time delivery can be guaranteed.

ENVIRONMENT

An appropriate environment motivates quality-conscious working by employees.

RESPONSIBILITY

Each individual accepts responsibility for the quality of their work and the immediate rectification of any faults that are detected.

Process

Thanks to a modern, process-orientated QMS according to ISO-9001, we comply with laws, ordinances and standards.

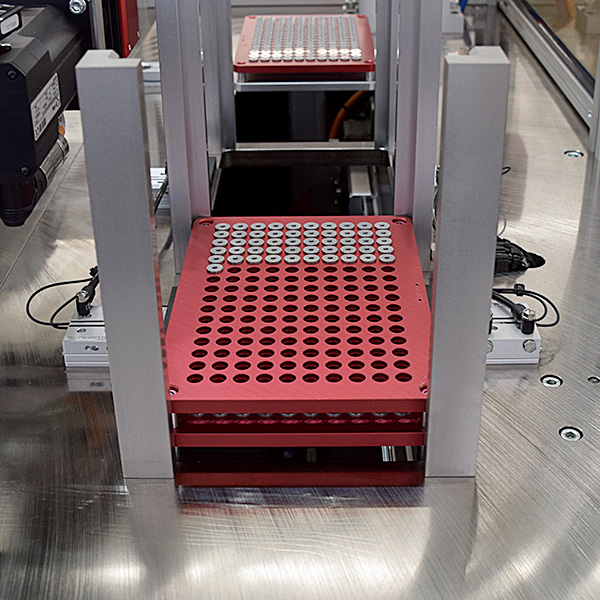

FINAL INSPECTION

Various test benches ensure that only faultless products leave our premises. Once a workpiece has passed through all processing steps, it is subjected to a very stringent final inspection.

In the case of hydraulic valves, amongst others this includes function, power, seal and flow rate testing.

Also, the presetting of our pressure-relief valves is carried out as part of the final inspection. The test pressure is adjustable between 60 and 600 bar.

We recently put into service a new test station for hydraulic valves that was manufactured especially for us and according to our specifications.

Working by hand is vital for these tests which are accurate to the millibar.